CM60 Series

WA Grouting Systems introduces a newly upgraded range of continuous grout pumps in a heavy-duty designs for the Australian mining, civil and exploration industries.

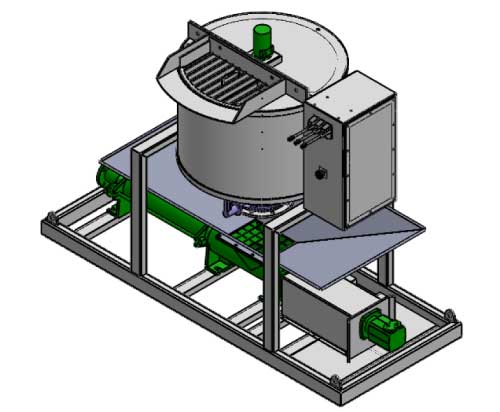

The unique design of the new WAGS CM60 grout pumps enables the operator to mix and grout in a continuous cycle.

The 300-litre mixing tank first mixes the cement and water, following which the mixture is fed into the 300-litre holding hopper via a large 125mm butterfly valve. Once the mixture is in the holding hopper, the operator can initiate the grout pump and grout while simultaneously beginning a fresh mixing cycle.

The newly upgraded helical rotor pumps boast 24 bar of pressure and flow rates up to 200 LPM.

WA Grouting Systems can design and build the CM60 in any size and format you require.

Key features of the WAGS CM60 grout pumps:

- Available in pneumatic, hydraulic and electric versions

- Available in standard form or in the new cable bolting design

- Complies with all safety standards ie a grate on the mix tanks, emergency stop

- Mounted on a heavy-duty skid and designed to fit in IT baskets or trailer mounted

- Quick couplers for easy installation.

- Hydraulic version incorporates a sturdy central control unit containing the operating levers and an emergency stop

- Flow control valves enabling variable speed located on the pump and mixer motor